iThink dynamic modeling improves freight and passenger transportation systems on Latin America’s borders

Graciela Sicra

Graciela Sicra

For developing countries, building international trade capabilities is often the key to economic success. Trade opens new markets and allows small producers to grow. It invites tourism and

job opportunities for migrants and immigrants who will contribute their earnings to local economies. Implementing systems that control efficient trade is often the challenge that gets

between trade aspirations and actual economic gains.

ICCs aim to improve the operational efficiency of border crossings and ensure the integrity of control processes for both freight and people

“Since 1959, the Transport Division of the Inter-American Development Bank (IADB) has worked to improve the fluidity and control of freight and passenger processes at borders,” says

Graciela Sicra, Principal of OMN Systemic Strategy, an isee systems consulting and training partner. “Through several projects, it developed the concept of Integrated Control Centers (ICC).

Specializing in freight and passenger systems, each ICC functions as a binational city; within its boundaries, there is free movement of people and goods.”

ICCs aim to improve the operational efficiency of border crossings and ensure the integrity of control processes for both freight and people. To increase efficiency, ICCs have to decrease

the unplanned down time that is often the result of private agent staffing practices or unanticipated flows of people and freight. Decreasing downtime depends on a thorough understanding

of people and freight transit flows and the ability to continually optimize control processes.

Using the iThink models, analysts interact with complex systems and explore, design, and test management policies and processes

Dynamic Modeling

To get a deeper understanding of the flows moving in and out of their transit systems and the relationship of those flows to staffing levels, ICC project experts turned to iThink models

developed by OMN Systemic Strategy. “Using the iThink models, analysts interact with complex systems and explore, design, and test management policies and processes,” says Sicra. Working

with ICC analysts, OMN developed iThink management flight simulators for all ICC projects in Latin America at Southern Cone country borders, as well as borders with Peru, Ecuador, Columbia,

Panama, and Costa Rica.

Each project uses two models, one for passengers and one for freight, that support both the initial planning and design of each center and its operations after construction. At the planning

and design stage, the simulator provides a solid base for sizing parking facilities, passenger and freight lines, and control posts using actual field data and projections that look out 20 years.

After the ICC has opened, the simulator provides a consistent, shared method for analysts and decision makers to determine if operational targets will be achieved and to test additional actions

that will be required.

By using models, ICC analysts are able to demonstrate how the concept works and its benefits to the countries and cities involved

Each simulator captures the processes observed at existing sites, thus allowing scenario analyses that compress time and space in a framework that emphasizes:

- Transparency: The structure of the model is available and the results are displayed numerically and graphically

- Flexibility: Models support a wide variety of complex scenarios. The data can be exported to an Excel spreadsheet

- Consistency: The behavior of the model is consistent with observed data from existing sites

- Accessibility: The users interact through a user-friendly interface on laptops in real time

- Robustness: The models capture the operational details specific to each user category and vehicle

By capturing key elements of the ICC operation, the simulator allows rapid experimentation with facility-routing proposals and the future operation of the complex. “ICCs impose many changes at

border crossings,” says Sicra. “By using models, ICC analysts are able to demonstrate how the concept works and its benefits to the countries and cities involved.”

Simulator User Interface

The custom-designed simulator user interface makes it possible for analysts who have no training or experience in systems dynamics or modeling to interact with passenger and freight control

processes. The impact of their decisions are displayed using indicators, tables, and charts. By changing the operational parameters, analysts can verify the validity of their proposals under

a variety of scenarios.

Using actual data and projections, it determines the number of entry lines, control booths, and physical review docks needed to process each type of freight transit

For example, analysts optimize the passenger control process by modeling flows of people in each direction through the ICC’s control facilities, looking at both mode of transportation

(foot, car, or bus) and classification of person (tourist, immigrant, or citizen of neighboring country).

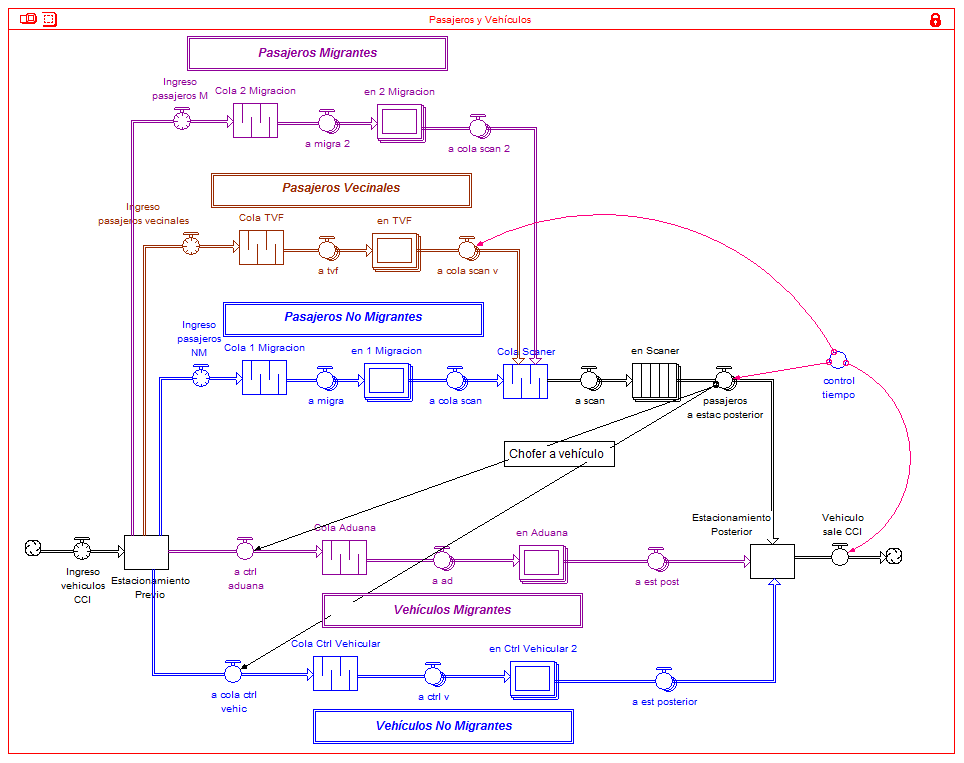

Passenger model structure

Passenger model structure

A setup and analysis screen provides a quick overview of ICC operations and is sensitive to changes in demand (passenger flow over time) scenarios. Analysts can test and determine the

processes and facilities (number of booths, scanners, parking places, etc.) needed to accommodate any number of passengers without causing downtime and/or long queues.

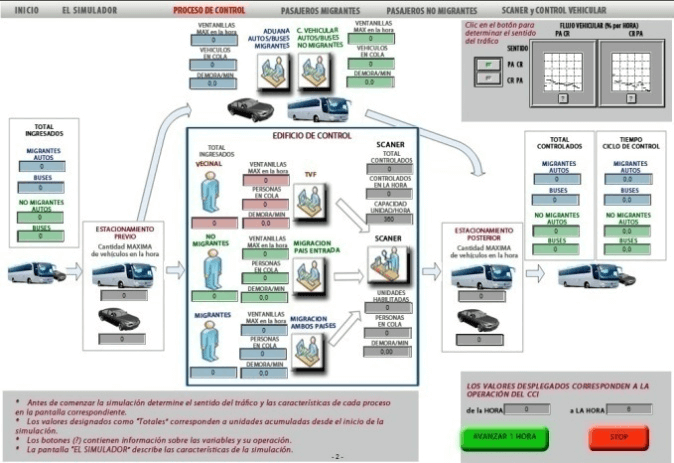

Setup and analysis screen by each type of passenger and controls

Setup and analysis screen by each type of passenger and controls

A separate passenger interface allows analysts to vary the number of cars and buses moving in each direction, the number of passengers per vehicle, and the types of passengers moving in each direction

to understand how queues build and wait times change. They can then test operational and staffing level remedies.

By opening the appropriate number of lines and managing staffing levels, ICCs are avoiding bottlenecks and reducing queues

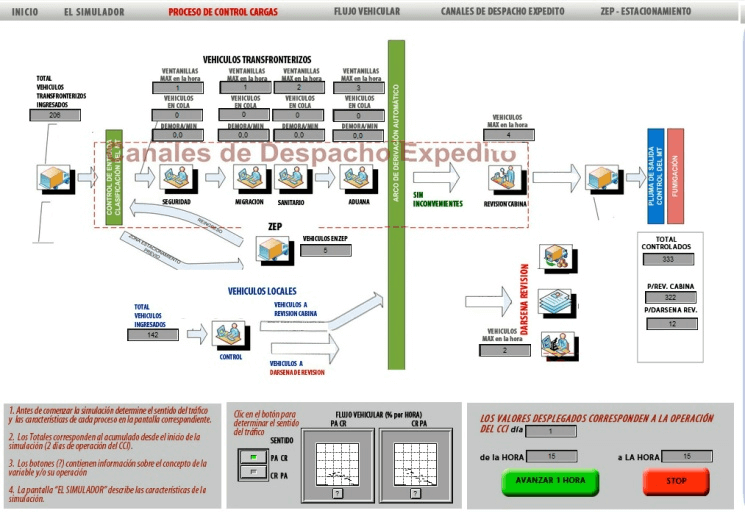

The simulator also includes the control process for both local and international freight vehicles. Using actual data and projections, it determines the number of entry lines, control booths, and

physical review docks needed to process each type of freight transit. Analysts can also experiment to determine how staffing levels influence queue times.

Freight setup and analysis screen

Freight setup and analysis screen

Using controls on the Expedited Dispatch Channels screen, analysts can set the average time needed for each freight process per line. The simulator then displays the status of each process along

with the number of vehicles in the queue, the maximum waiting time, and the maximum vehicle load each hour.

Modeling insights and benefits

Using this simulator, ICC analysts have moved beyond reporting on transit processes to experimenting with modifications to optimize each process and overall operations. “Managers are determining

resource allocations according to traffic flows expected on each shift over a 24-hour period,” says Sirca. “By opening the appropriate number of lines and managing staffing levels, ICCs are

avoiding bottlenecks and reducing queues.”

The model was built with sufficient flexibility and data to support even extreme scenarios for up to 20 years

While the simulator has led to changes in ICC operations, Sirca doesn’t anticipate changes to the model itself. “The model was built with sufficient flexibility and data to support even extreme

scenarios for up to 20 years. If and when it’s needed, we’ll be able to change the model to align with any modifications to the ICC concept, its basic processes, or its layout.”